[Glass Tube Fuses]

Upon hearing the word fuse, many people first picture a glass tube fuse consisting of a glass tube that contains a metal element. Glass tubes were used as early as the 1910s to prevent accidents due to overcurrent during engine ignition. However, these fuses abruptly moved into the spotlight in the 1970s. Against the backdrop of air pollution problems linked to vehicle emissions, automakers developed engine control units (ECUs; microprocessor-based engine controllers) with the aim of maintaining engine performance and fuel efficiency while complying with emissions regulations. The development of ECUs triggered a sudden acceleration in the adoption of automotive electronic solutions. This in turn increased demand for fuses, which play a role in ensuring the safety of electric circuits and the protection of devices.

[Blade Fuses]

Blade fuses (auto fuses) were developed in 1975 and continue to be the mainstream fuse type utilized in vehicles today. Compared with glass tube fuses, blade fuses require only half the parts, their simplified structure is ideal for mass production, and they are smaller, lighter and more durable. Amid the shift toward electronics in the automotive sector, blade fuses were rapidly adopted by automakers around the world.

[Slow Blow Fuses]

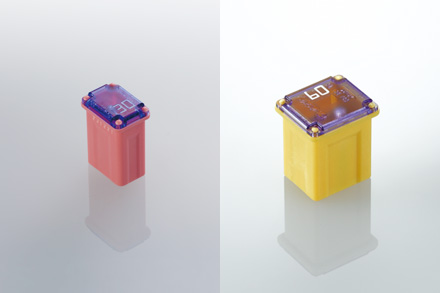

The 1980s introduced a range of automotive electronic solutions aimed at enhancing passenger comfort, including power windows and automatic wipers. As a result, vehicles came to be equipped with a large number of motors. However, motors temporarily produce a large current that exceeds their rated capacity when they are switched on. Conventional auto fuses, which immediately blow when exposed to overcurrent, were therefore not appropriate for this type of application. Instead, automakers employed slow blow fuses, which are distinguished by a slow rise in temperature when exposed to high current and therefore do not blow immediately. PEC developed slow blow fuses in 1982 ahead of its competitors. Moving into the 2000s, automotive ECUs grew increasingly complex, resulting in the need for miniaturization of the circuit itself. The product that emerged to meet these needs was the multi slow blow fuse, which protected multiple circuits.

[EV Fuses]

From the mid-1990s, automakers started exploring the concept of environmentally friendly vehicles, giving rise to the EV fuse. Electric-powered vehicles require much higher currents than their gasoline counterparts. For this reason, conventional fuses would immediately blow and the high current would give rise to another problem in the form of the arc discharge phenomenon that could lead to destruction of circuits. The EV fuses developed by PEC in cooperation with Toyota Motor became the first products to resolve this problem, and have been adopted in the hybrid vehicles of a large number of automakers. They have also been installed in electric vehicles that have been developed to deliver additional environmental performance since the 2000s.