Building on a rapidly expanding R&D structure to develop products for the next generation of automobiles and beyond.

We established our R&D Group in 2012 with the aim of developing not only automotive fuses but also various component technologies while anticipating trends in the automotive market and related technologies over the next 10 to 20 years. With the introduction of tougher environmental regulations (e.g., NOx or CO2 emission regulations in various countries, California’s Zero Emission Vehicle Program), the shift toward electronic solutions and weight reduction in the automotive market is expected to further accelerate. Moreover, the rise of driving safety support systems and automated driving systems will almost certainly lead to the installation of an even higher number of sensors per vehicle. In accordance with such trends, we intend to take up the challenge of further developing devices based on ceramics technology and materials capable of withstanding high-energy exposure while leveraging our circuit protection technologies and expertise cultivated through fuse development. We believe forward-looking R&D requires a flexible mindset to avoid being restricted by conventional ideas, and we accordingly strive to bring together diverse human resources from inside and outside the company, combine knowledge in a way that transcends specialized fields, and produce groundbreaking innovation.

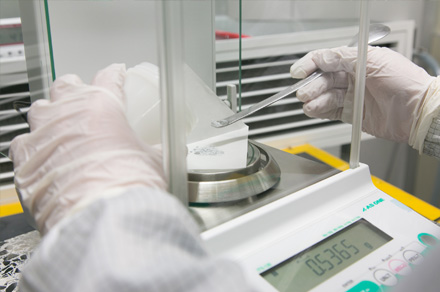

Our R&D efforts can be summarized with the keywords “weight reduction,” “shift to high-energy solutions,” “advanced functionality” and “cost reductions.” To achieve weight reductions, we actively work to develop processing technologies for new materials. Prompted by the need for larger-capacity batteries and faster charging, we continue to develop component technology with an eye toward creating fuses that can withstand high-energy exposure exceeding 1000V. In our pursuit of advanced functionality, we look beyond traditional fuse technology, review the foundations of materials usage and design, and have also started development of ceramic devices. In terms of cost reductions, we design development processes for basic fuse assembly technology that take advantage of automation and device platform consolidation, and transcend the limits of conventional equipment design.

We have also partnered with academic institutions that have accumulated cutting-edge knowledge in our R&D fields. We actively exchange opinions with our partners to fine-tune our ideas, and enhance the reliability of our research data through careful analysis.

We intend to further accelerate our R&D efforts to help support the automobiles of the future and beyond.