It is said that Thomas Edison, the inventor of the light bulb, first put forth the idea of a fuse. Ever since, fuses have been widely used across a wide range of applications to ensure the safety of electric circuits and protect devices.

Electric circuits are connected to various devices through electric wiring and switches that receive electricity from a power source. Fuses are installed in series with the electric circuit on the upstream flow of electricity and are designed to immediately interrupt the circuit when exposed to overcurrent resulting from a short-circuit on the downstream flow. They are therefore critical components that protect the wiring and devices in an electric circuit from damage caused by fires and the like.

When exposed to overcurrent, a fuse’s metal element, which is distinguished by a small cross-sectional area, reaches its melting point and subsequently blows. This effectively interrupts (protects) the circuit.

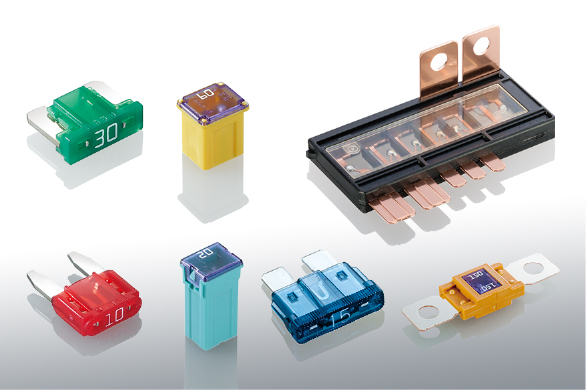

Fuses are classified into different types depending on their usage purpose and application. For example, there are fuses for high-voltage insulating structures, cylindrical fuses for applications that receive or distribute electricity, tube-type fuses used in residential electric appliances, surface-mount fuses for printed wiring boards, and automotive fuses.

Automotive Fuses

BF (Quick blow type)

SBF (Slow blow type)

MUSB (Slow blow type)

Even when confining the discussion to automotive fuses, these can still be divided in a wide range of types based on usage purpose. (Figure 1)

Among this large variety of automotive fuses, the type that has made most headway with standardization and is currently employed in vehicles all over the world is the blade fuse (BF). In recent years, the number of fuses installed per vehicle has increased in tandem with wider adoption of electric and digital systems in automobiles, an increase in the number of on-board devices, and a shift to increasingly compact fuses.