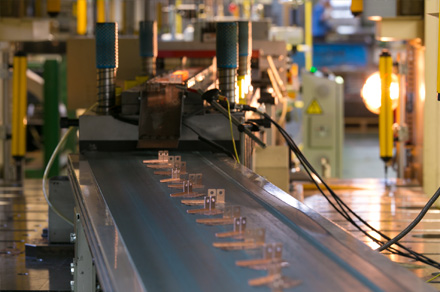

Precision Metal Forming

Characteristics of the press-forming business

We achieve high-precision processing through a combination of unique die-related expertise and processing technologies.

Pacific Engineering Corporation’s (PEC) superior processing quality for press-forming products is supported by its in-house die production technology. Our product portfolio includes engine mounts (which support automotive engines), drum brakes (which help vehicles come to a definite halt) and fuses and elements (which help protect electric circuits). Although these components are small in size, they play an invaluable role in supporting the safety and reliability of the components or structures that integrate them. Taking advantage of our long years of expertise and advanced technology, we utilize press-forming processes to manufacture products such as high-precision parts for fuses and automotive parts made from high-tensile steel plate.

±0.002mm and Higher Die Processing Precision and 0.06mm-wide Punch-Press Processing

Fuse characteristics change depending on the width of the metal wire and the precision of the utilized process. This change is particularly evident in the case of fuses with a current capacity of 5 ampere or less. PEC has continued to deliver reliable products through its high degree of processing precision.

Support for Die Production for Press Machines Up to 600t

Automotive press-forming products such as multi slow blow fuse elements and brackets require high pressure. PEC possesses the technology to produce dies for a 600t press machine.

Support for Ultra-High-Tensile Steel Plate Processing Up to 780Mpa

Ultra-high-tensile steel plates, which combine a high degree of hardness and tensile strength, retain their strength even when their thickness is reduced. For this reason, they are increasingly utilized in automotive and other parts, where weight reduction is an important consideration. We have achieved press-forming processing for high-tensile and difficult-to-process steel plate based on the production of high-precision dies, optimized processing procedures and expertise in machine operation. In this way, we are able to meet the needs of automotive companies with advanced requirements.

Two Distinct Technologies: Plate Processing and Forming Processing

We utilize plate processing and forming processing, and accordingly receive orders for press-forming products, assembled resin products and insert forming parts.