Meeting the demands of the prevailing times through technology and innovative thinking in step with developments in the automotive industry

Fuses are an indispensable part of automobiles. The evolution in automobiles has propelled advances in fuses, while the invention of new fuses has conversely supported the development of new automobiles. Since PEC entered the fuse market in 1970, it has developed cutting-edge fuse products and contributed to the advancement of the automotive industry.

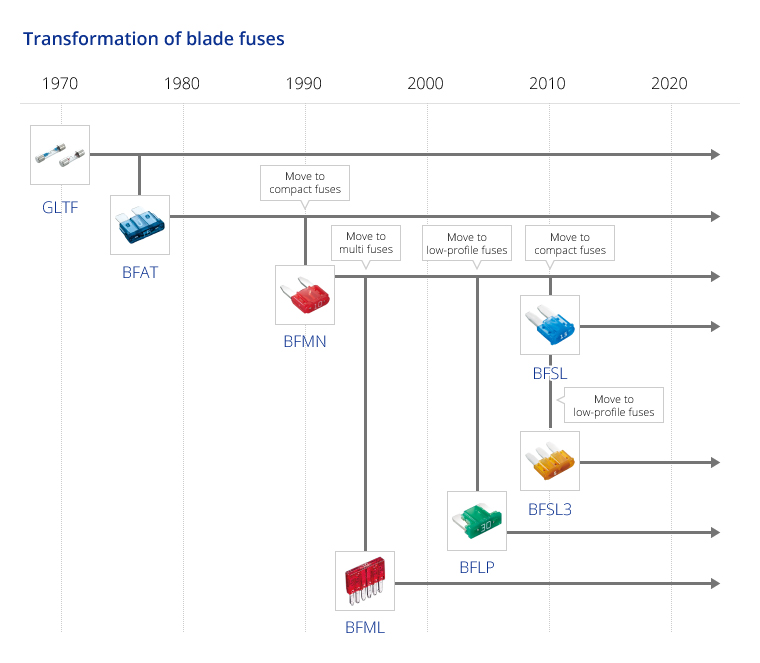

Blade Fuses

In 1960–70, automobiles were equipped with glass tube fuses, which were manufactured by hand at the time. PEC became the first company worldwide to successfully achieve automated mass production of such fuses in 1971, thus responding to the needs of various sectors including the automotive industry. Not long thereafter, in 1975, the company started production of blade fuses (auto fuses), which have become the most common type of automotive fuse in use today. Compared with glass tube fuses, blade fuses have a simpler structure and excel in terms of size (more compact), weight (lighter) and durability. PEC recognized the utility of blade fuses early on and has accumulated extensive manufacturing expertise for this product. Blade fuses have been successively adopted by automakers, leading to widespread usage. Prompted by automaker calls for products tailored to the growing complexity of automotive electronics and miniaturization of circuits, blade fuses went through a series of improvements that gave rise to multi fuses and more compact versions, and these are currently still utilized in a large number of automobiles.

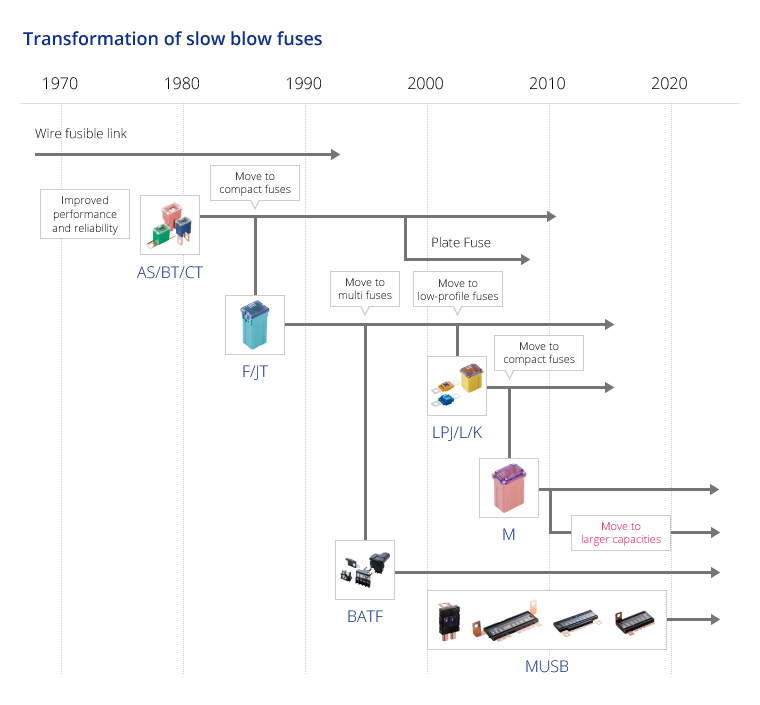

Slow blow fuses

Moving into the 1980s, automobiles continued to increasingly incorporate electronics, and the pursuit of enhanced driving comfort led to the introduction of various new functions such as power windows, automatic wipers and air conditioning. In conjunction with this trend, automobiles started featuring multiple motors. Auto fuses, which blow out immediately when their threshold capacity is exceeded, were unsuitable for motors because the latter generate a current that far exceeds their rated load when they are switched on. This meant a new type of fuse was needed. In response, PEC developed slow blow fuses that delayed the temperature rise accompanying high currents and therefore did not blow out immediately. The company started sales of slow blow fuses in 1982. The product was well received by the market and came to be used worldwide. From the 2000s, PEC expanded its product portfolio with multi slow blow fuses, which protect multiple circuits, to accommodate the growing complexity of electronic control systems used in automobiles.

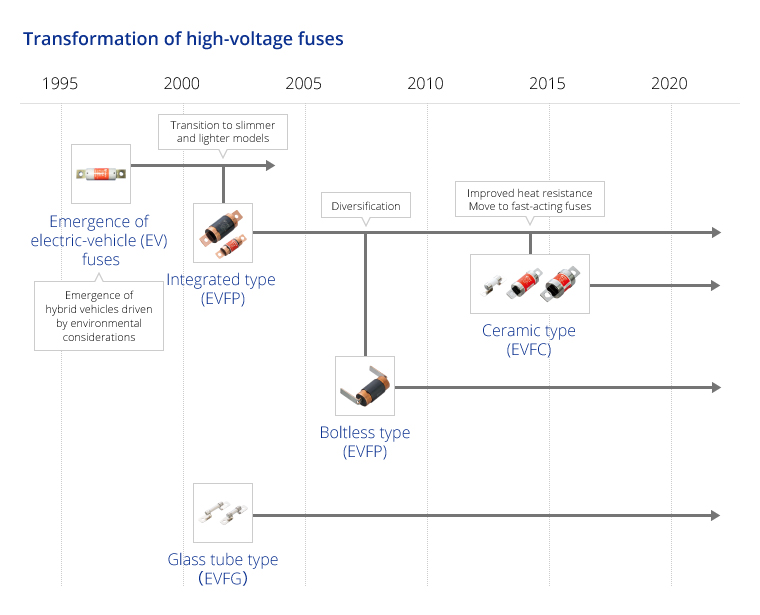

Electric vehicle fuses

From the late 1990s, automakers around the world started exploring the production of environmentally friendly vehicles. The most promising strategy at the time appeared to be the use of electricity as a power source for driving. Automakers thus ramped up development of hybrid vehicles, which combined conventional engines with electric motors, and electric vehicles (EVs). However, the resulting next-generation vehicles required an entirely new type of fuse. Electric-powered driving entails much higher voltages than on-board electronics and conventional fuses could not accommodate the higher voltages. In addition to blown fuses, another problem was that the high voltage could also give rise to an arc discharge phenomenon that would result in the destruction of circuits. To resolve these issues, PEC developed dedicated EV fuses for hybrid cars in 1997. The new fuses were adopted in the first hybrid vehicle that year and by various automakers later. To this day, they continue to be used by virtually all automakers around the world in a wide range of applications, and they have also been adopted in F1 and other racing vehicles.